High-performance waste cardboard balers

We offer manual and automatic baling presses for the effective compaction of paper, cardboard or carton waste.

Compacting your paper and cardboard waste saves transport costs, working time and storage space. Benefit from the advantages and strengths of an Austropressen baler. We will be happy to advise you on the best solution for your company.

Visit us at a trade fair

Paper presses & cardboard presses for every application

- Loose cardboard

- Edge trims & cuts

- Paper reels

- Edge trims & cuts

- Paper reels

Paper & cardboard balers

Paper and cardboard waste comes in countless forms and quantities and is generated in every business, especially as packaging material. The use of balers to compact these recyclable materials is essential for sustainable businesses. Austropressen products guarantee heavy and dimensionally stable bales of high quality for maximum storage and transport capacity.

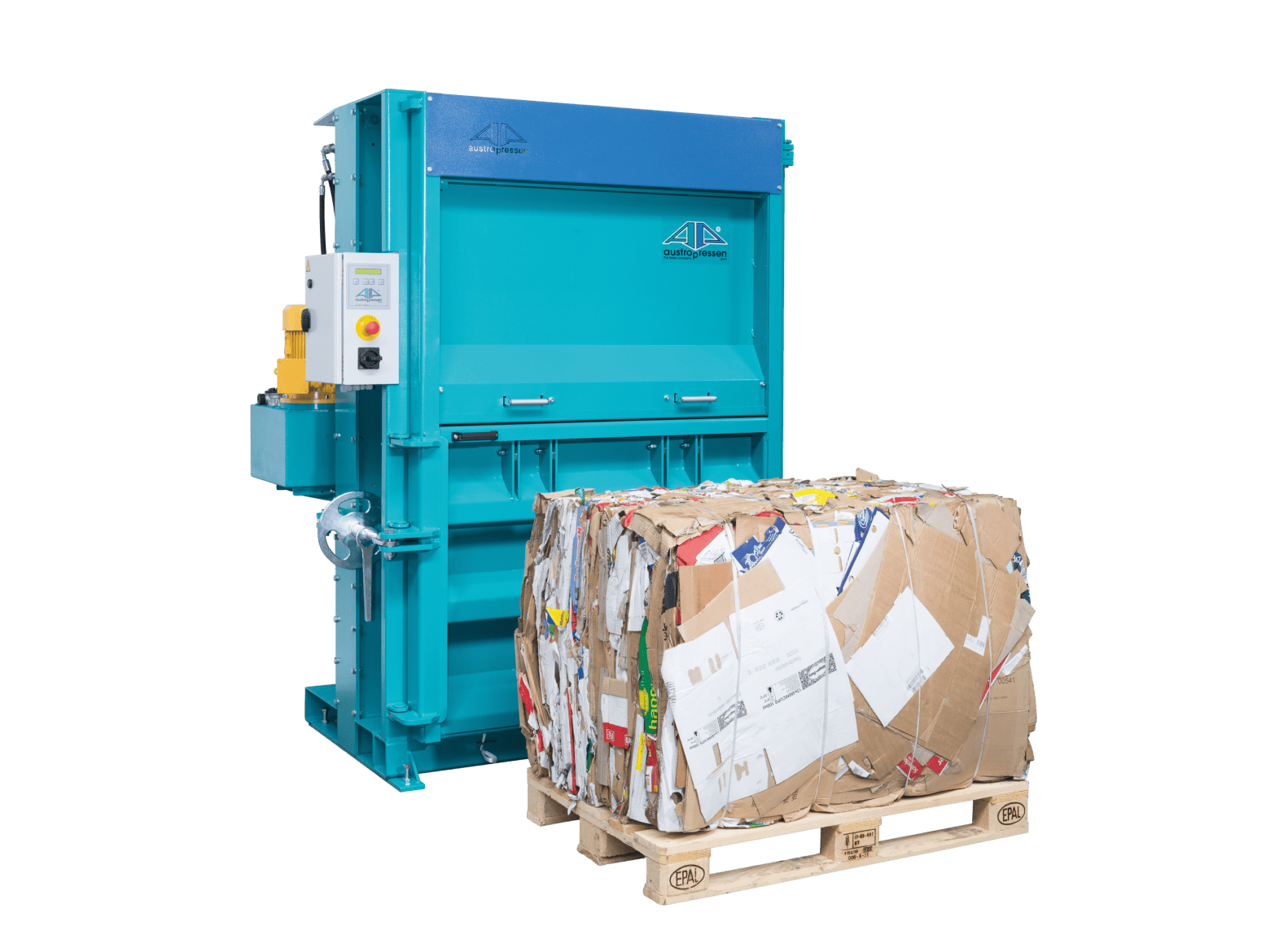

Vertical Balers

Our range offers a variety of space-saving compaction masters for bale weights from 50-500 kg.

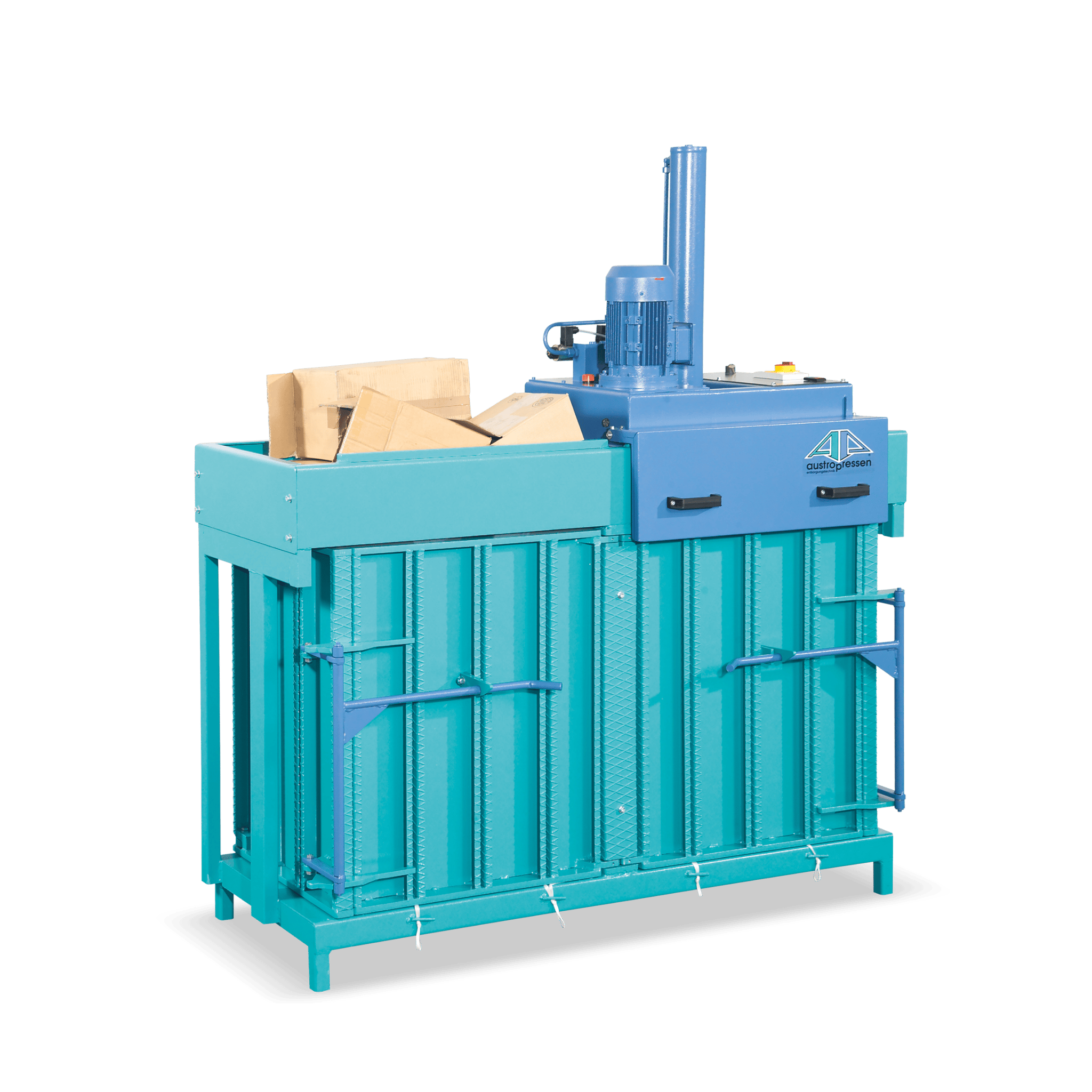

Multi-Chamber Balers

Using our flexible multi-chamber balers makes sorting, collecting and baling raw materials simple and efficient.

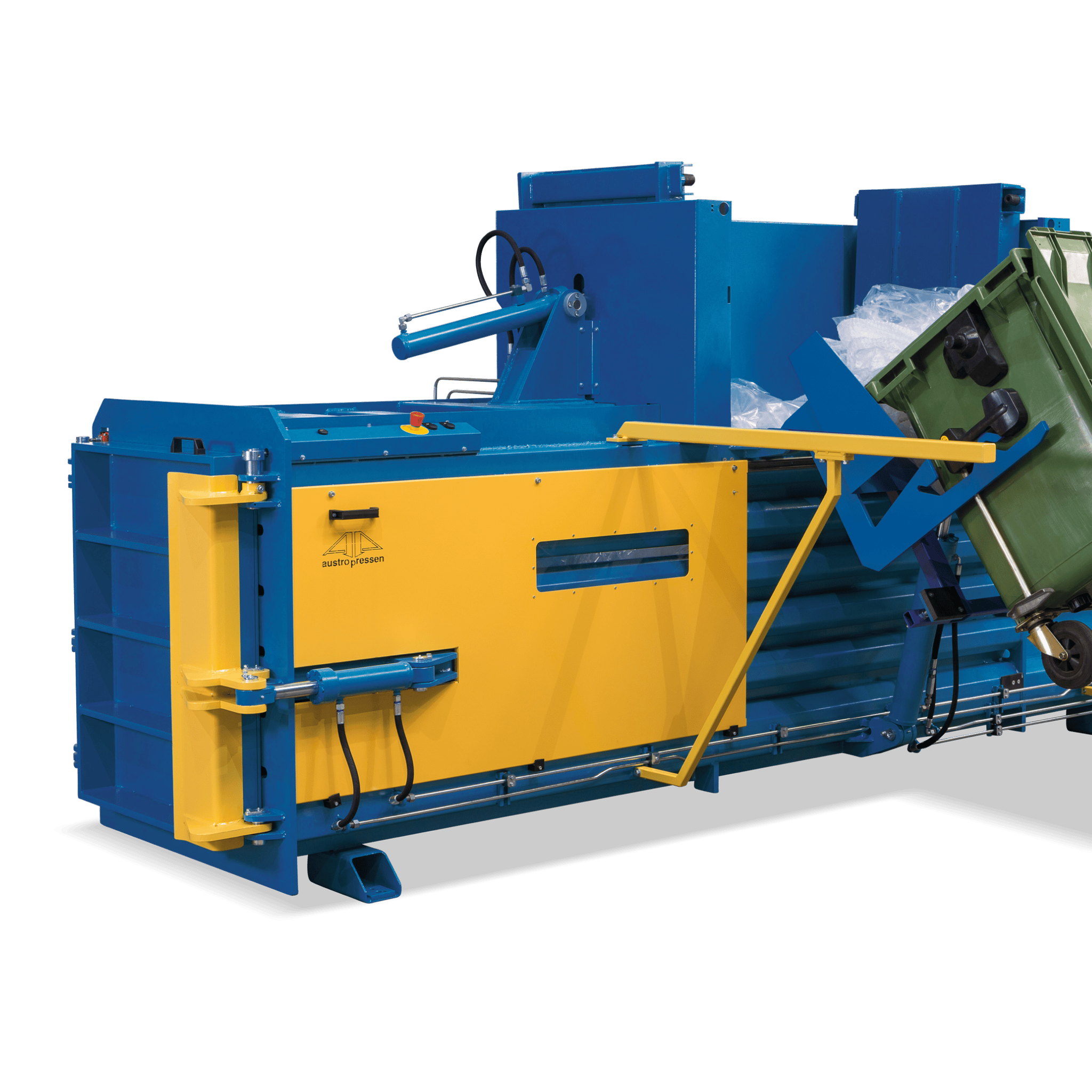

Horizontal Balers

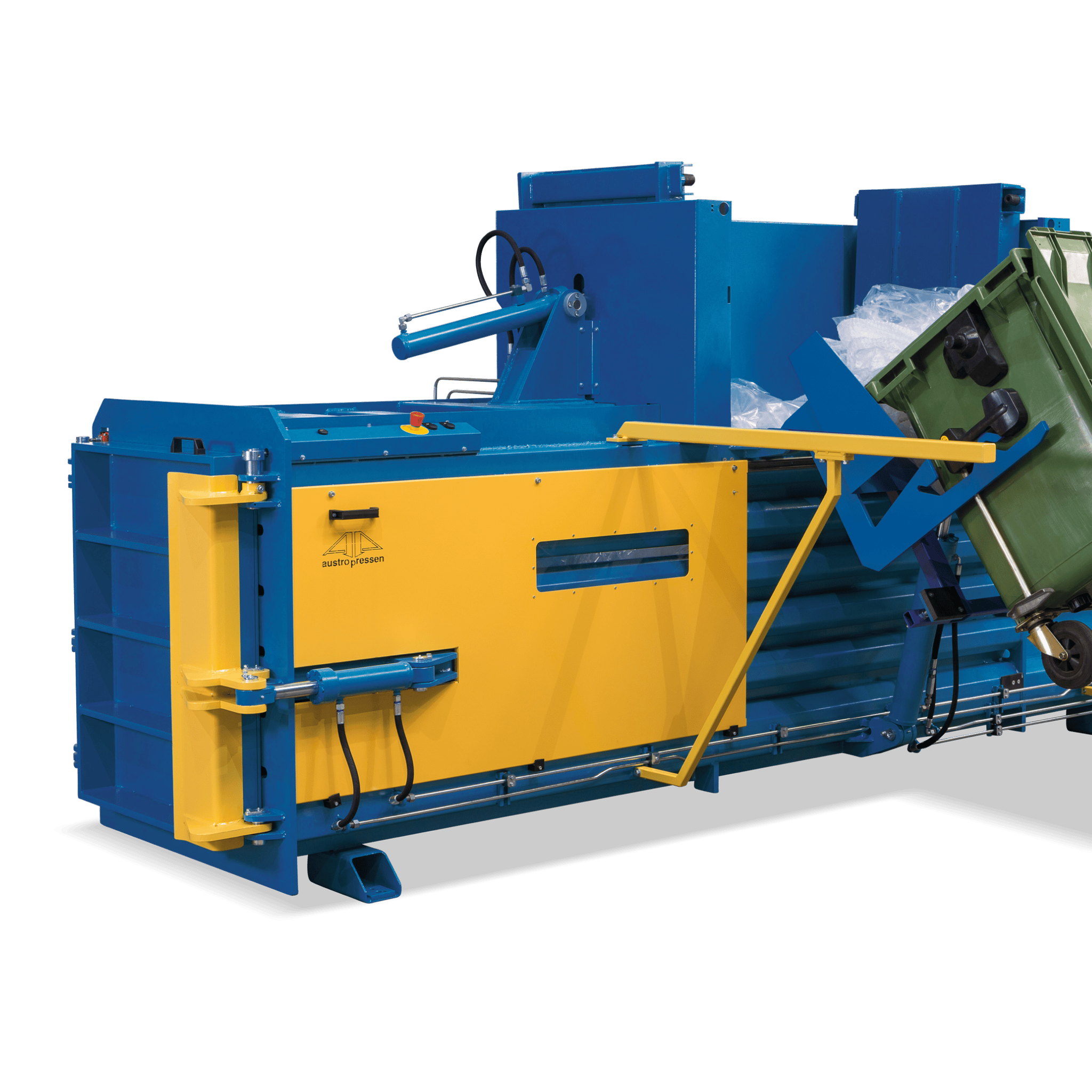

Manual and semi-automatic baling presses with various filling options, e.g. with a tipping device.

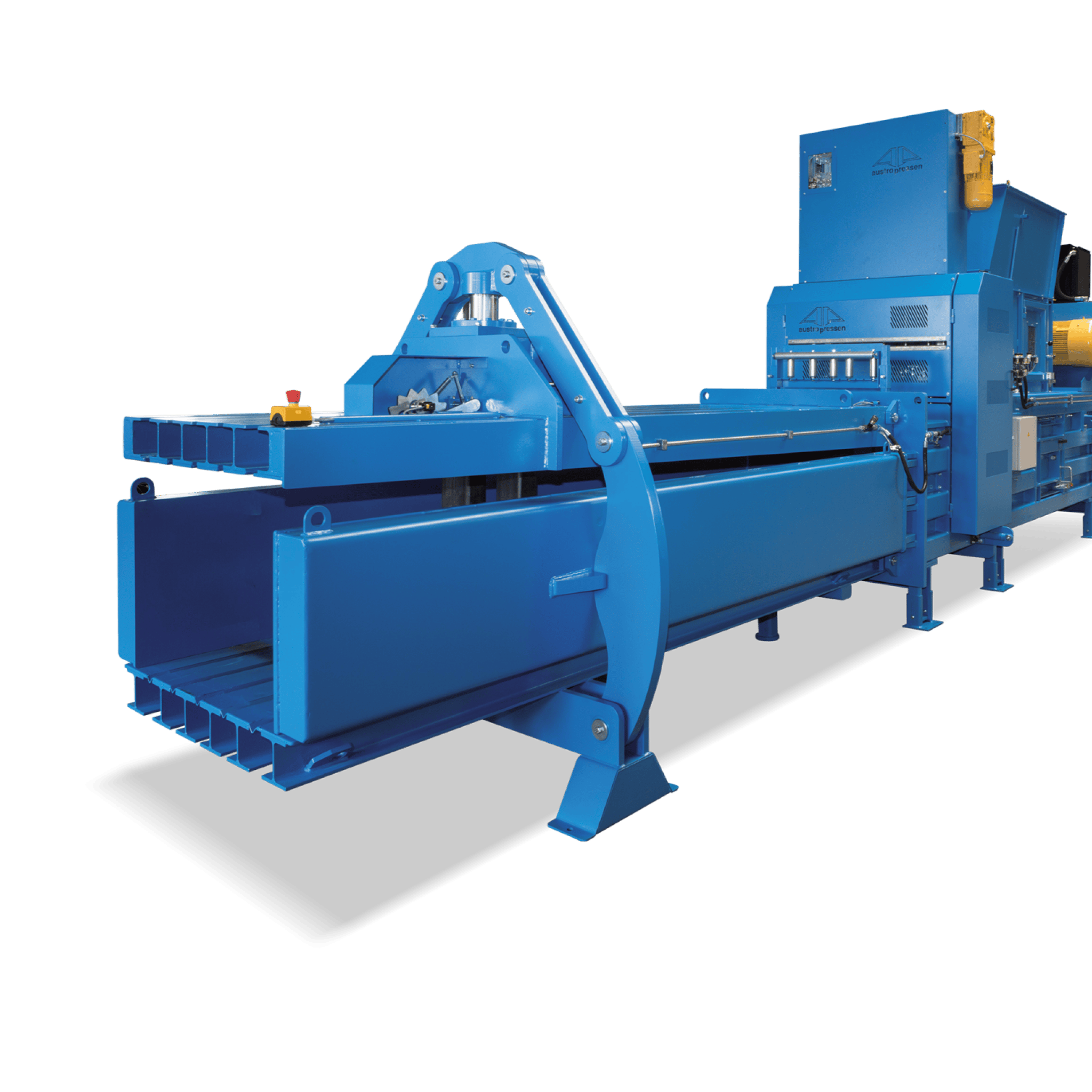

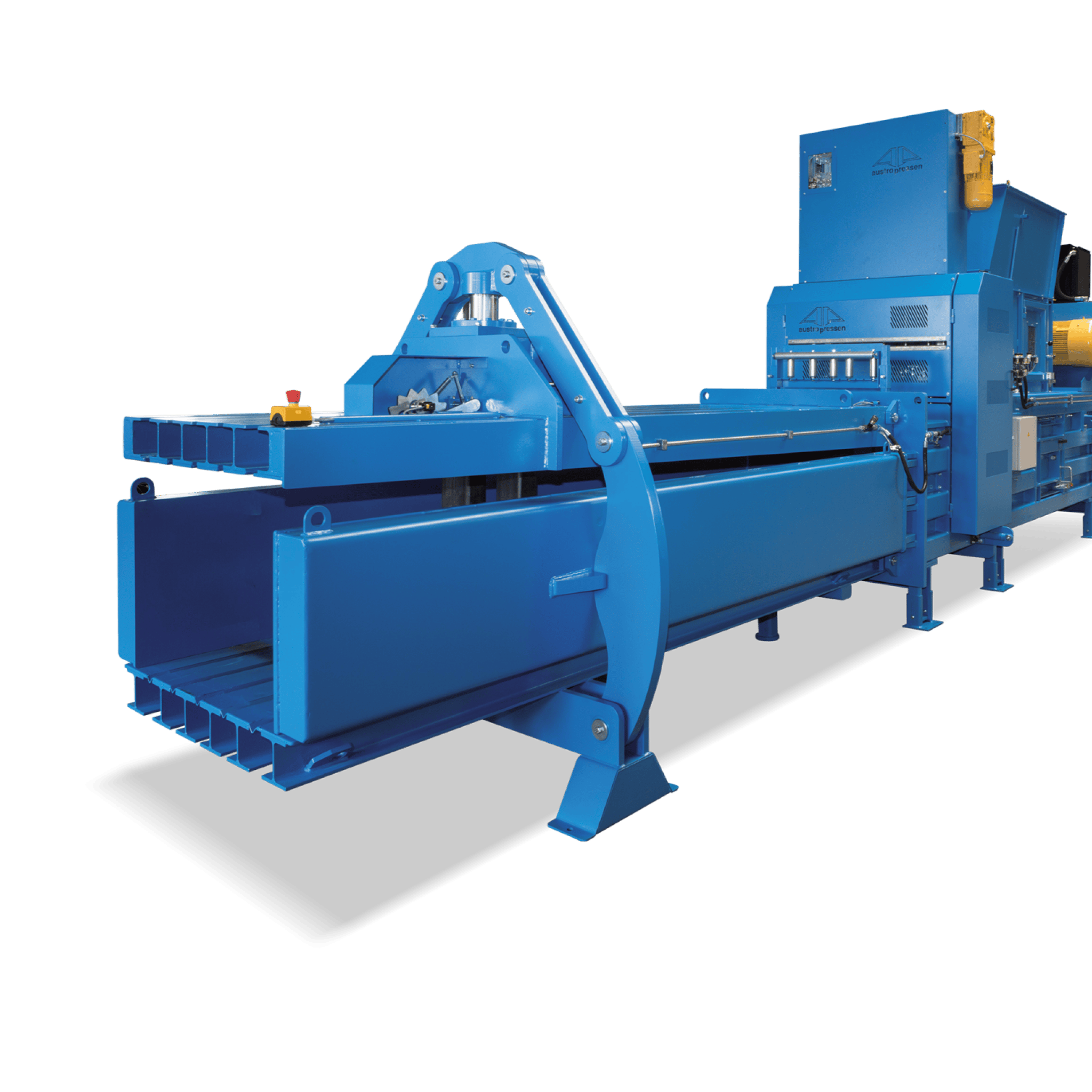

Automatic Channel Balers

Fully automatic and continuous processing through to the finished bale of cardboard or paper with our APK channel balers.

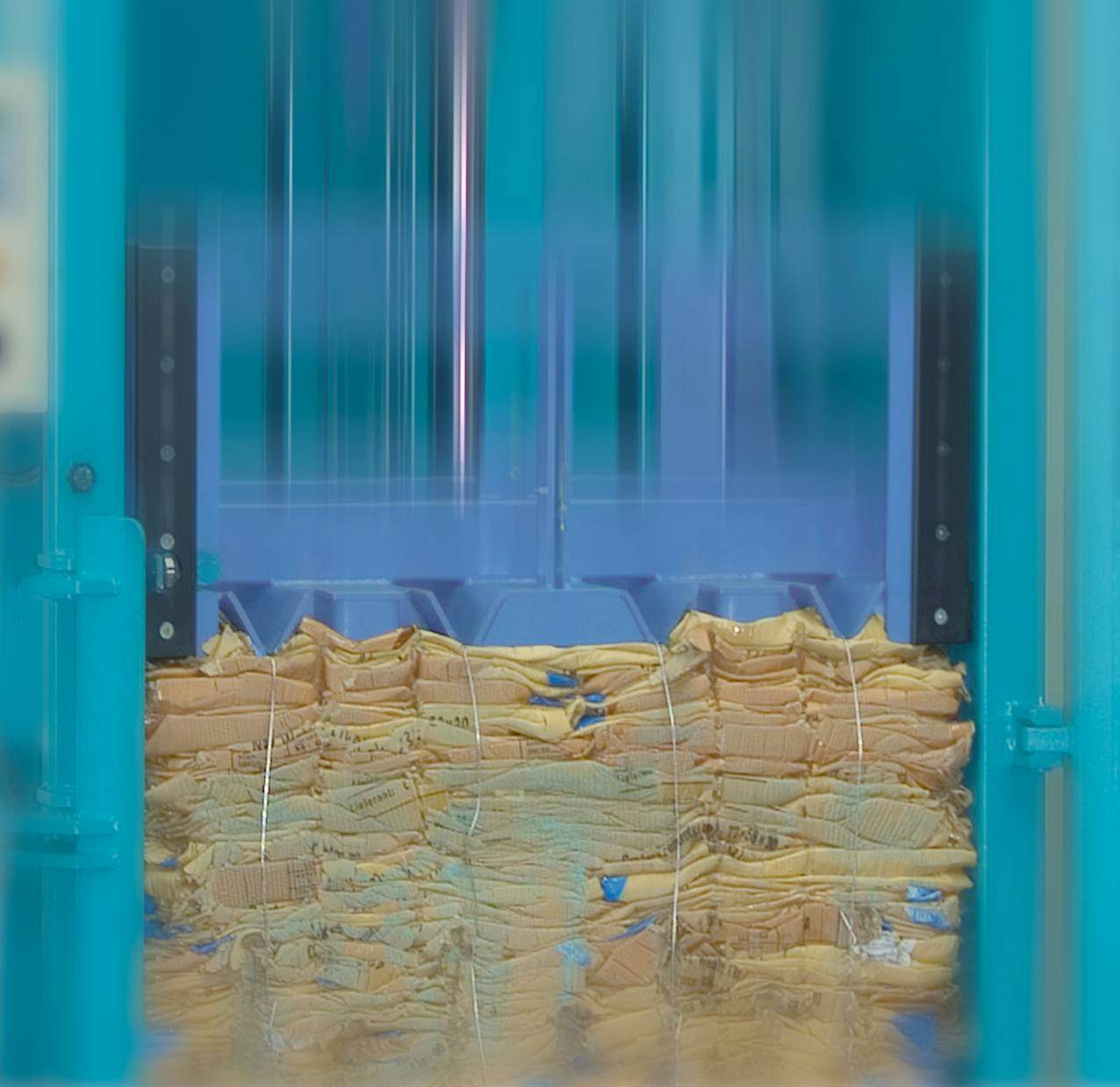

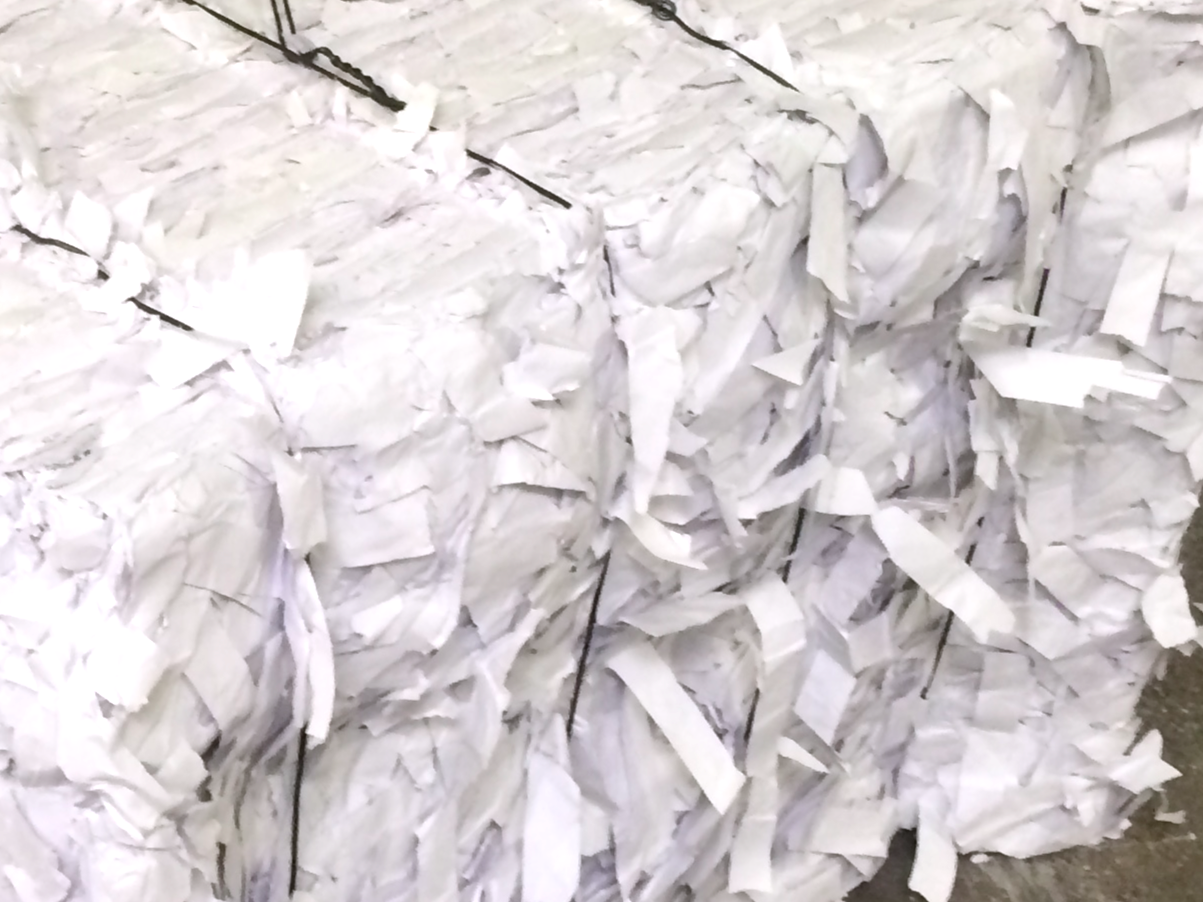

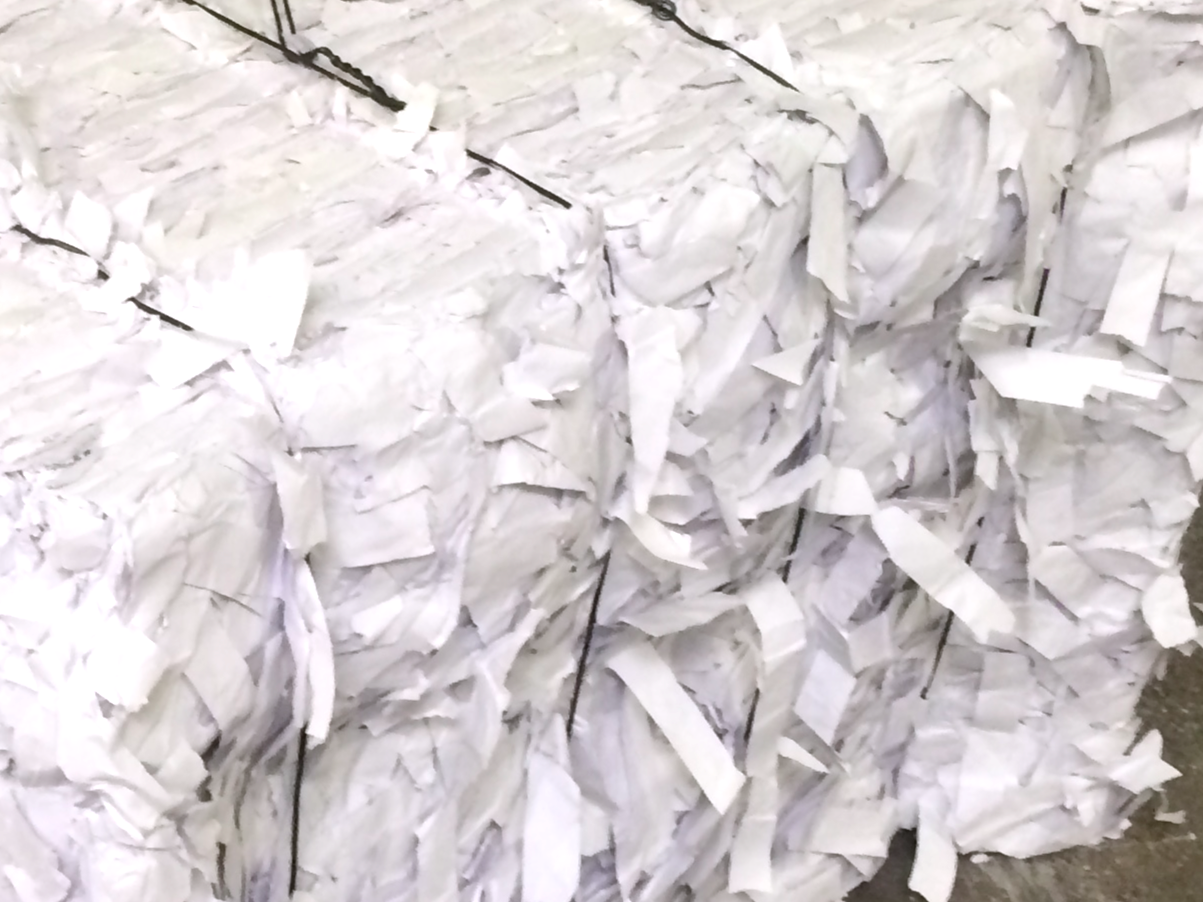

Balers for production waste

During the manufacture of paper and cardboard products, edge trim or punching waste is produced. These are collected by extraction systems and pressed into bales for further recycling. We offer semi-automatic and fully automatic solutions for the compaction of production waste, as well as for shredded paper from document destruction.

Horizontal Balers

Semi-automatic and cost-efficient baling presses for packaging production and industry.

Automatic Channel Balers

Fully automatic and continuous processing through to the finished bale of cardboard or paper with our APK channel balers.

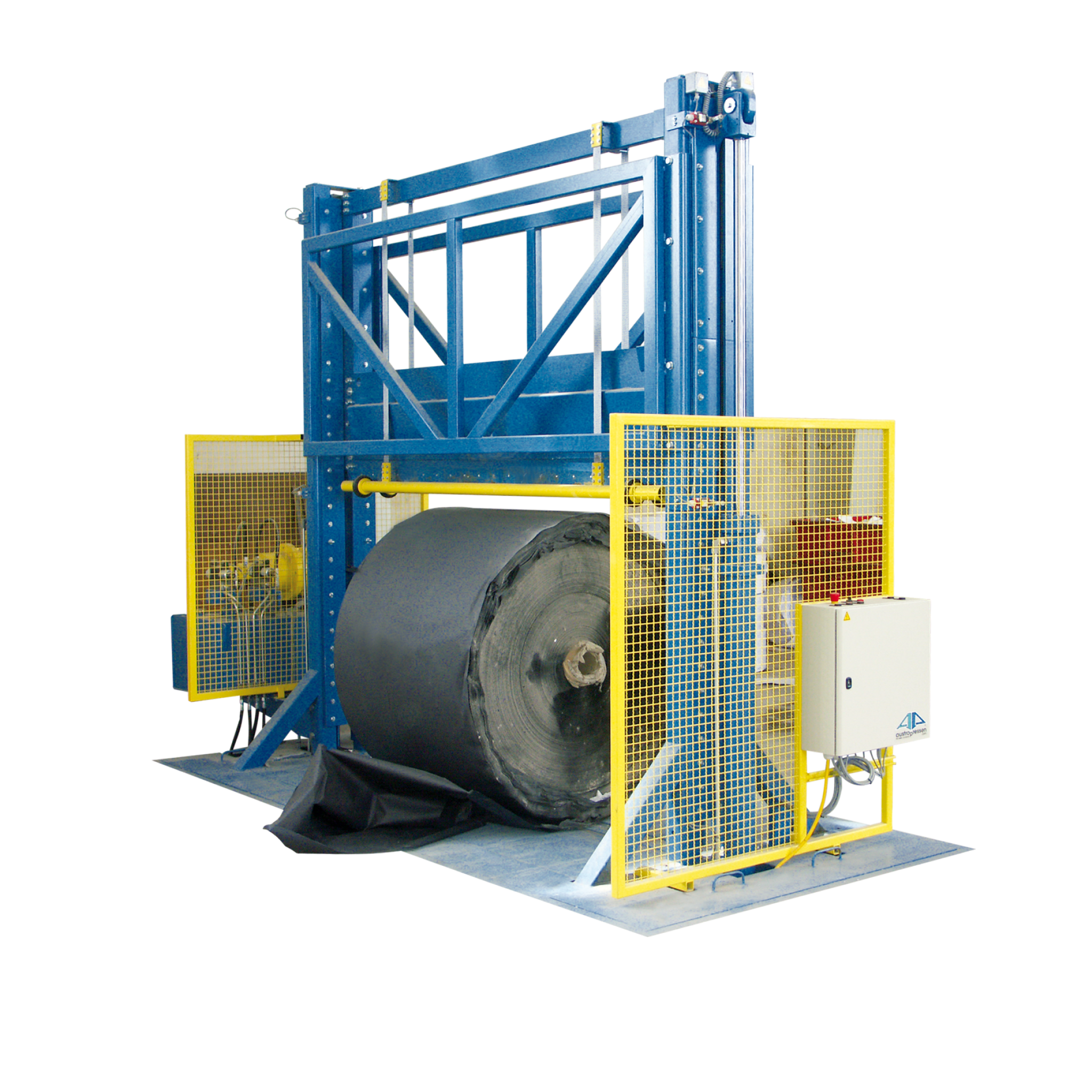

Guillotines for paper reels

Our range includes a large selection of roll slitting machines (also known as guillotines) for waste and scrap rolls of paper. These guarantee effortless slitting and shredding of rolls up to a width of 4000 mm and a diameter of 2000 mm.

Reel Splitting Machines (Guillotines)

We also realise customised solutions with conveyor systems from Austropressen for a smooth operating process.

Benefits of compacting paper and cardboard waste

Take advantage of the benefits of compacting your waste and recyclables:

Our automatic channel balers for cardboard at our customers

3x APK-D channel baling presses for Hermes Fulfilment

Hermes Fulfilment GmbH operates the central distribution warehouse for the Otto Group's trading companies. Hermes relies on three of Austropressen APK-D42 channel balers to handle the large volumes of packaging material quickly and easily.

Reliable high performance for the central warehouse of PENNY Germany

Penny's logistics centres are designed to use sustainable energy and recycle as many raw materials as possible. The APK-ES90 channel baling press from Austropressen makes a valuable contribution in the central warehouse in Eching/Germany.

Focus Future: Technik für die Zukunft.

Technology of the future. Our portfolio offers innovative, sustainable and energy-efficient solutions for small businesses as well as international companies in all sectors.

Long-lasting quality from Austria

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.

Take advantage of our experience.

Contact us and we will find the ideal solution for your company's use in a free consultation.