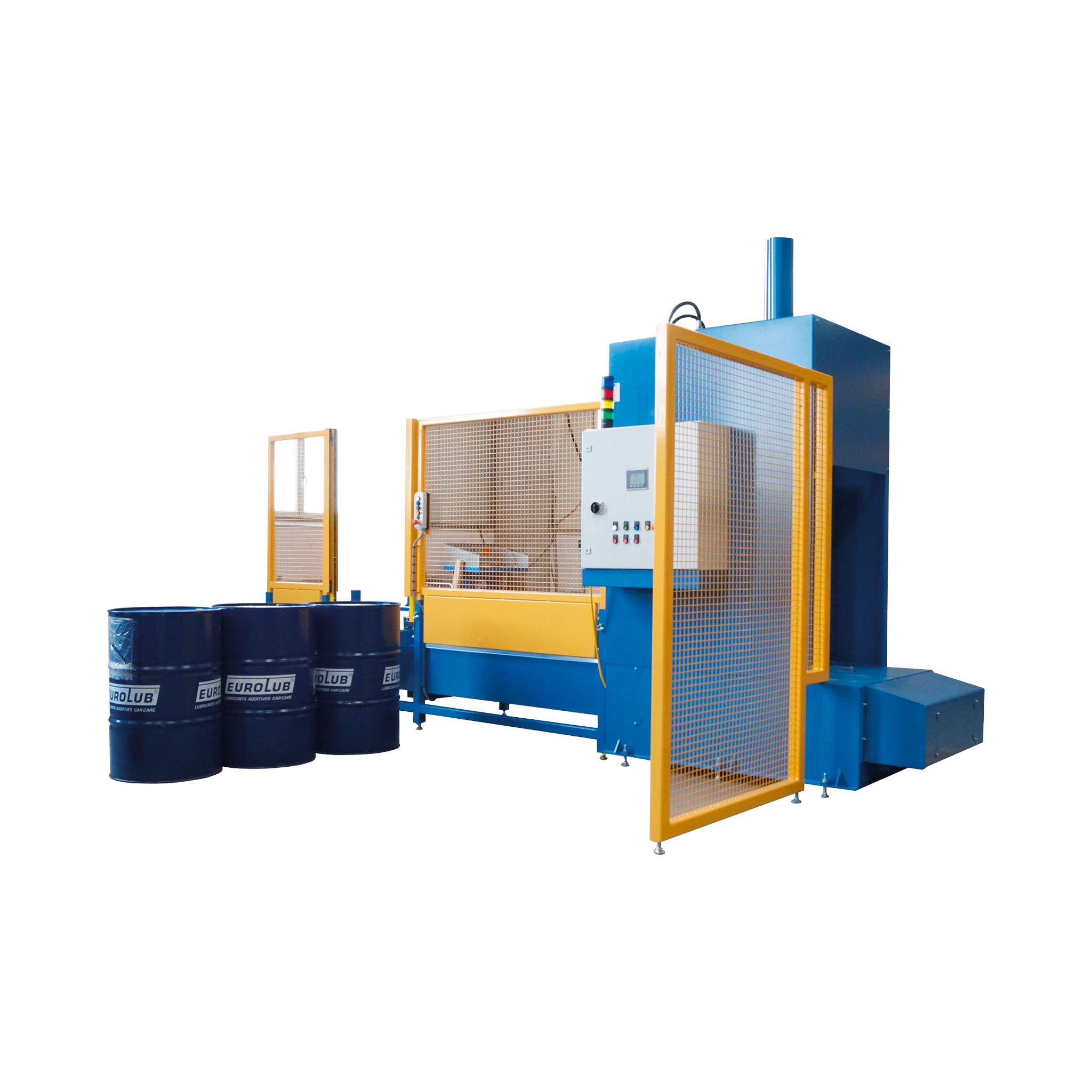

Barrel Press FP 200/300

High efficiency

Volume reduction up to 90% of drums, cans, barrels and containers up to 200 liter.

The press ram is fitted with spikes, allowing air or gas to escape during the compaction cycle. The presses are simple to operate and are equipped with an automatic ram return. Any liquid residues are collected within a sump.

The main benefits:

Short automatic pressing cycle

High pressure force & heavy duty

Integrated sump for liquid residues

Also available with ex-protection (ATEX) or with automatic feeding via conveyor.

Categories

Can & Barrel CrusherMaterials

MetalsNaN/undefined

Easy and quick operation: simple push button control and automatic return stroke of the cylinder

Fast processing thanks to short pressing cycle

Maximum operator safety due to closed construction

Press ram is fitted with spikes, allowing air or gas to escape during the compaction cycle

Space-saving: clean waste and storage rooms

Clean solution: any liquid residues are collected within the integrated sump

Model FP300 is also available as ex-proof version (meeting ATEX requirements)

High durability and reliability based on our Austropressen quality standards

- ModelleFP 200 | FP 300

- Press load200- 270 kN

- Driver power4- 5,5 kW

- Moudling cycle50- 60 sec

- Max. barrel height950 mm

- Throughput50- 60 pcs/h

- Dimensions (LxBxH)1000x890x2450- 1010x950x2500 mm

- Weight800- 1200 kg

All models and full technical data:

Successfully used in production companies, automotive indsutry, waste disposal companies for compaction of drums, cans, barrels and containers up to 200 liter.

Also available with ex-protection (ATEX) or with automatic feeding via conveyor.

Further products

Long-lasting quality from Austria

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.